After looking at our product range, you will notice that the products are divided into two series. These are bolt and rivet trailers and welded frame trailers.

Bolt and rivet trailer details are cut out of sheet metal and bent. They are connected to each other using rivets and bolts.

Trailers on a welded frame, as the name says, are made of steel tube frames that are very resistant to the various conditions. The frame ensures flexibility for the trailer and is not afraid of vibrations, and is therefore very resistant to the effects of the environment. For everyday use, we strongly recommend a trailer with a welded frame.

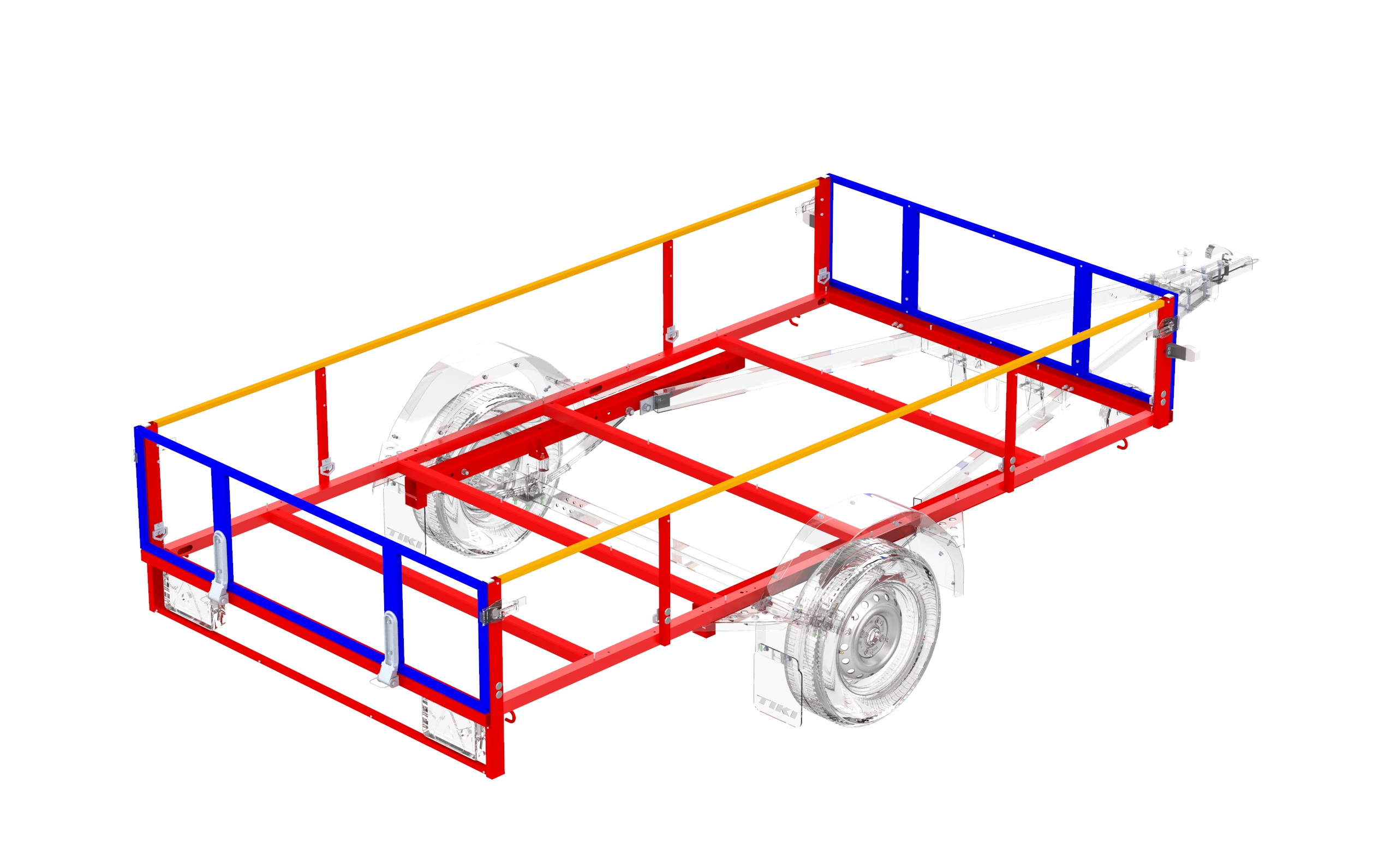

One of the most important factors in evaluating the trailer’s durability is the trailer’s frame. The design of the frame begins with the engineers’ 3D CAD drawing. The base frame and side port elements of Tiki trailers are welded together from laser-cut tubes and then hot-dip galvanized as a whole. This approach ensures maximum elasticity and corrosion resistance. This steel tube trellis structure prevents the frame from bending under load, and all the other components of the trailer are added to the frame later.

One of the great advantages of Tiki trailers is the steel tube that supports the top edge of the side port. Very necessary and important for better loading of the trailer, supporting weights on the port and attaching the load strap outside the port of the trailer.

The sides of the Tiki trailer are made of high quality sheet metal sourced from the largest metal manufacturers in Scandinavia. The sides have two stiffness profiles that ensure the side is inflexible, resistant to vibrations and accidental impacts caused by the cargo. These profiles have made our trailers look great for more than 30 years.

The hatches of Tiki trailers are openable and very easy to remove. The frame of the hatches is made of steel tube, which allows the customer to use the hatches as driveways for a smaller motorized vehicle (ATV).

The drawbar is made of a square steel tube with a wall thickness of at least 3 mm. The material ensures guaranteed strength and safe use of the trailer.

In the domestic market, trailers with leaf spring suspension are mainly used. Trailer axle beams are hot-dip galvanized. We use waterproof wheel bearings and hubs from the world’s leading manufacturers as Knott and BPW. The axles are equipped with shock absorbers that mitigate the impact of potholes on driving characteristics.

All Tiki trailers are equipped with a weather resistant laminated plywood bottom. The plywood has a non-slip surface coating pattern and the edges of the plywood are pre-treated to prevent moisture.

The electrical system of Tiki trailers uses pre-assembled and tested cables. To protect the electrical system from external damage, the wiring is hidden inside the trailer frame. At the same time, changing the cable is easy if necessary. The best visibility in traffic is ensured by lights from the top Austrian manufacturer Aspöck.

Tiki trailers are equipped with internal and external eyelets and hooks for securing loads.

Internal eyelets are placed on the inner sides of the cargo box and lean on the port frame posts to withstand greater tensile strength.

Tiki cargo trailers do not have internal eyebolts mounted on the bottom of the trailer, as this makes loading and transporting sheet materials difficult.

The functionality of securing the load is enhanced by strong hooks on the outer sides of the trailer frame, which are welded to the frame.

We provide the largest selection of desired accessories for Tiki trailers. The most popular products are plastic covers, tents, port highteners, spare wheel and motorcycle holder. To see the option of additional equipment for each trailer, please open the detailed view of the trailer.